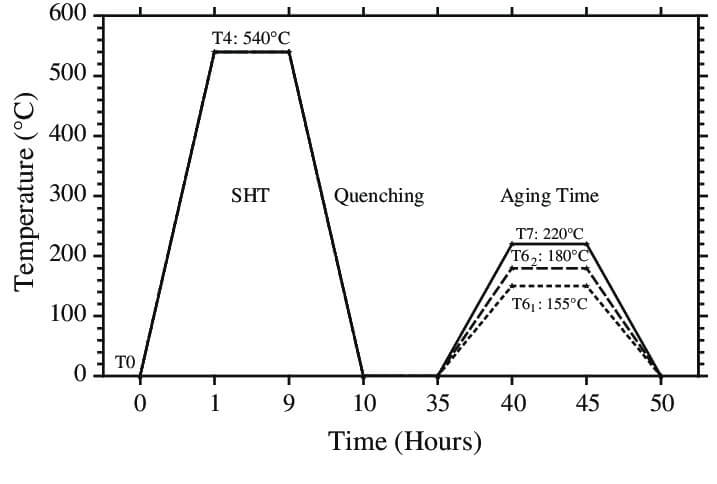

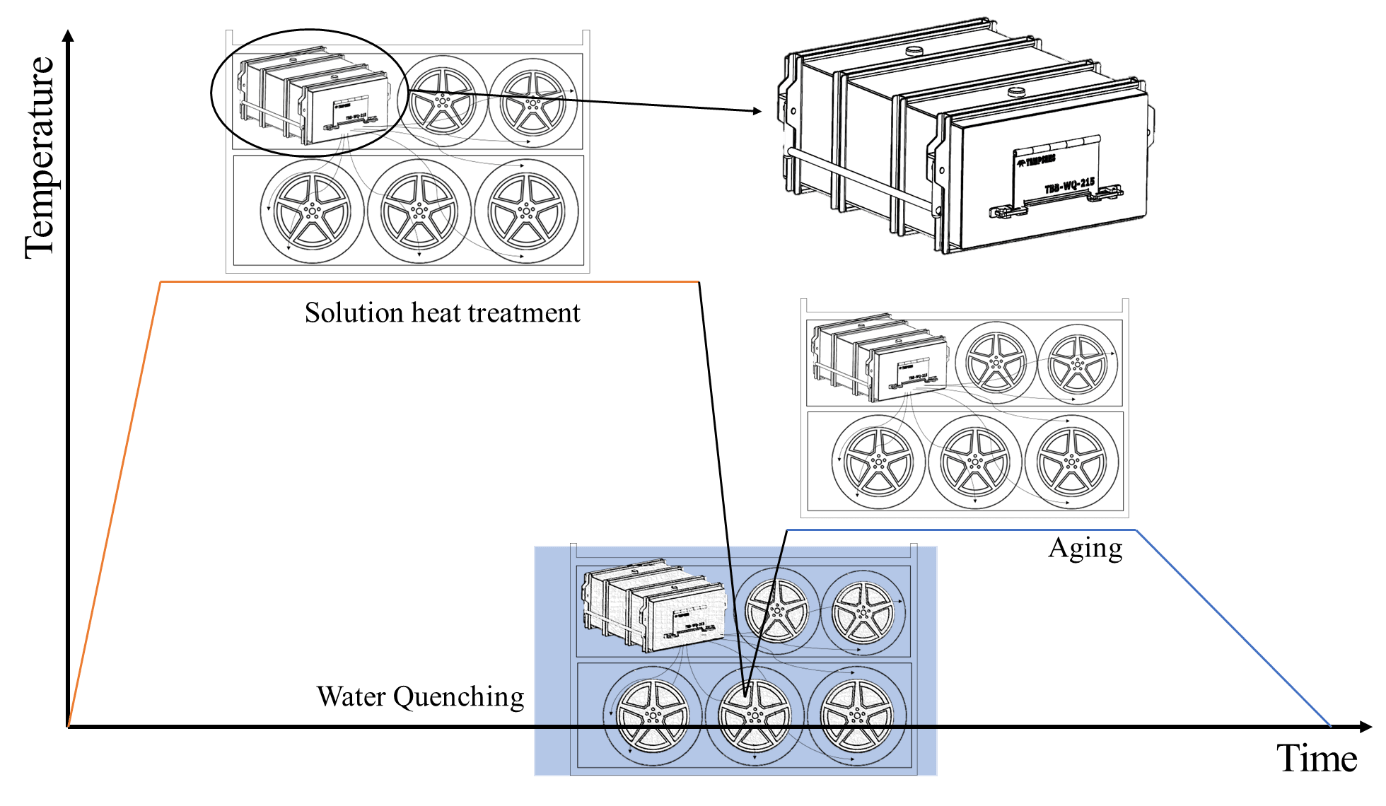

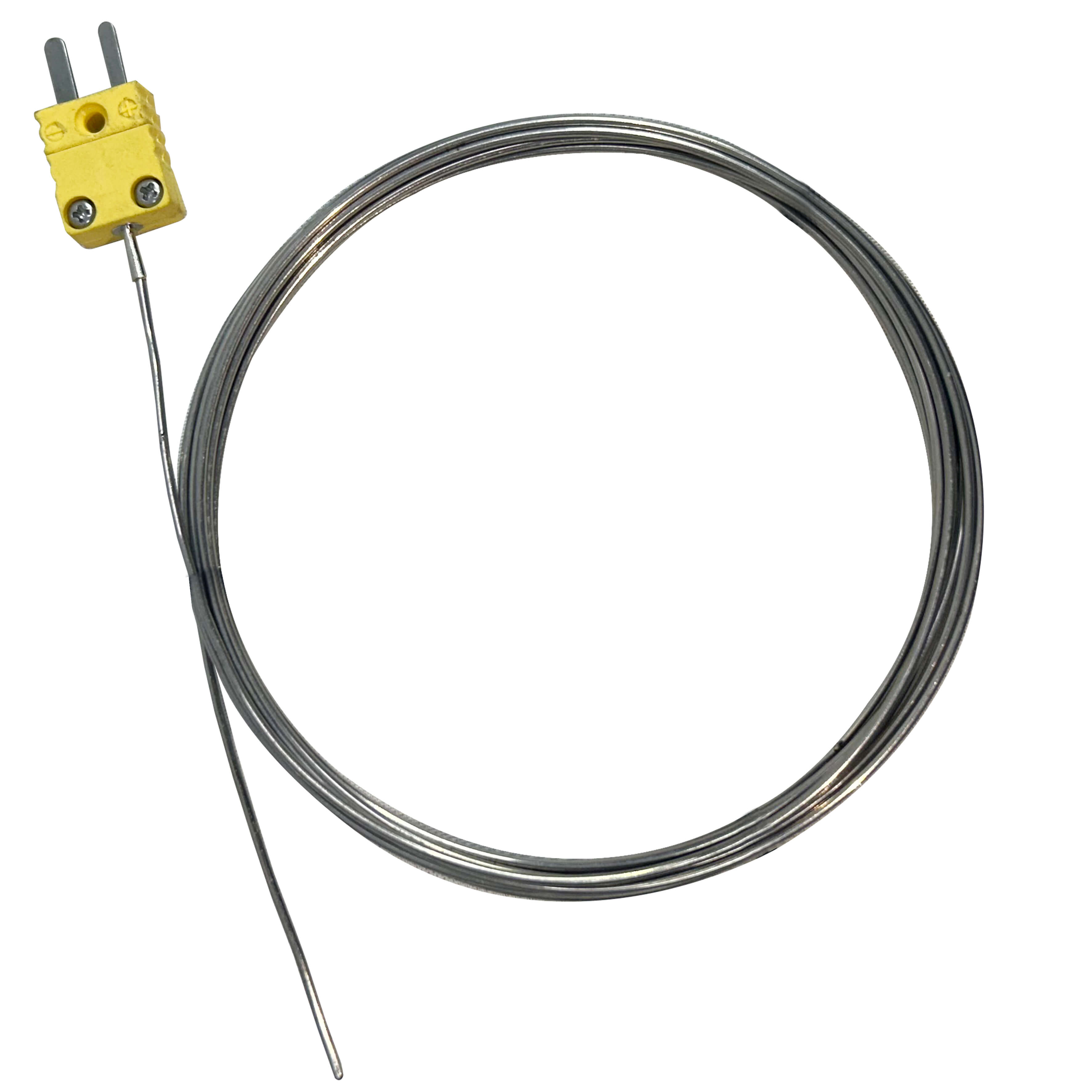

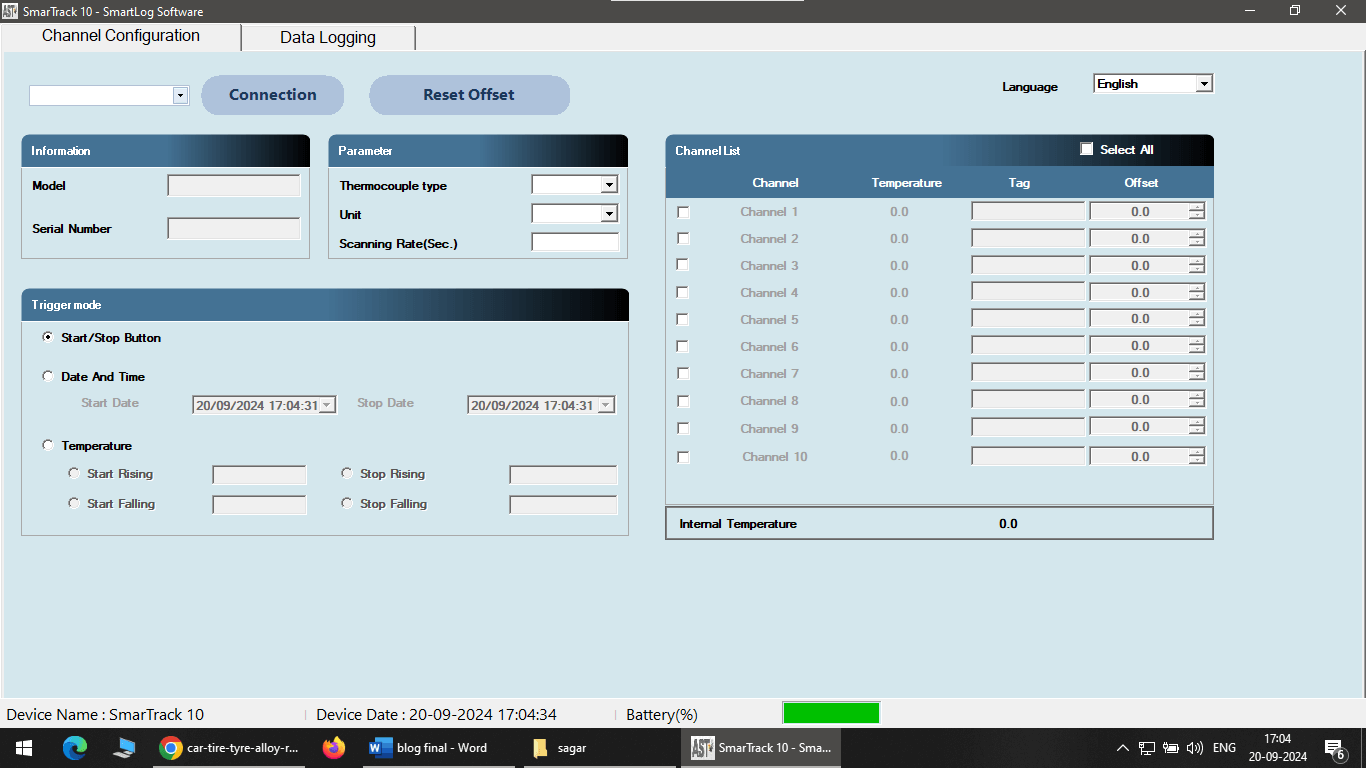

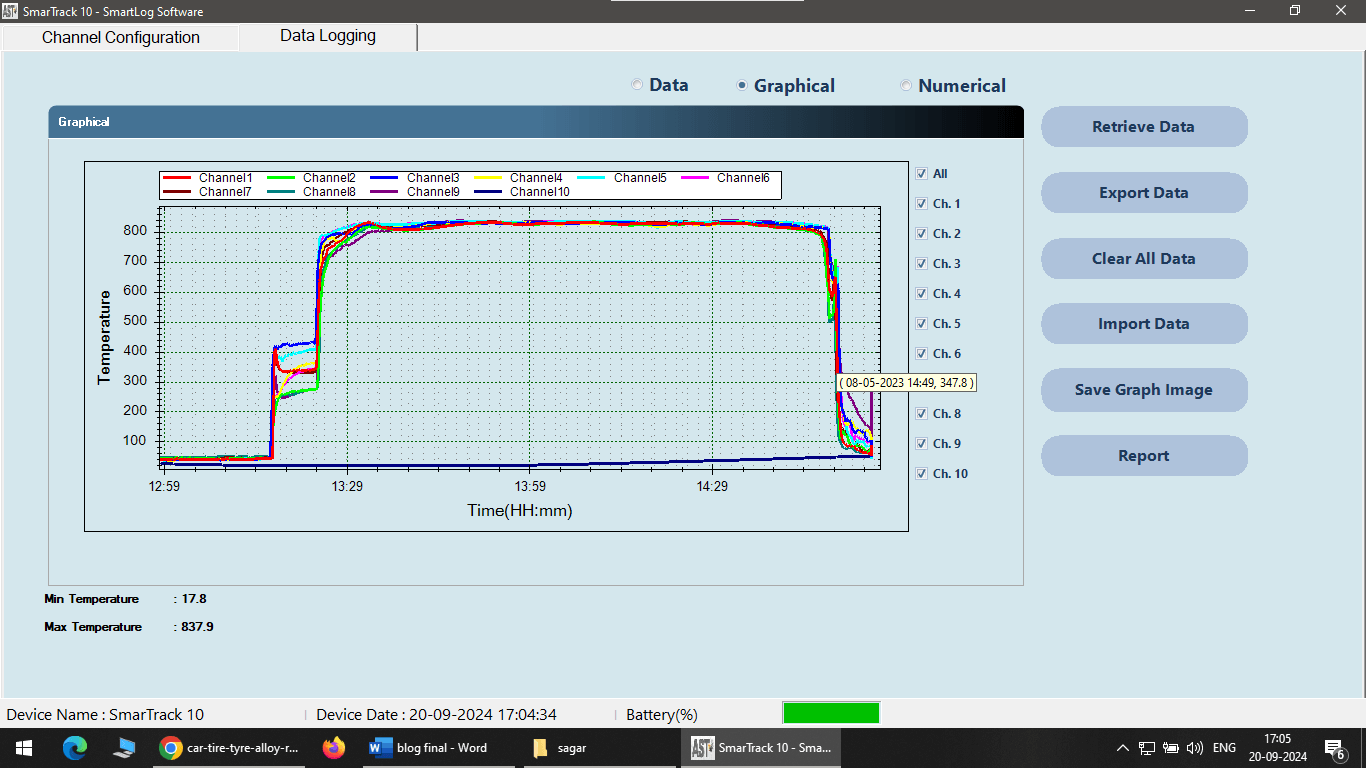

Aluminum heat treatment is a critical process that enhances the mechanical and physical properties of aluminum alloys, such as strength, hardness, and durability. This is achieved through precise heating and controlled cooling. Among the most common techniques are T6 and T7 heat treatments, which involve key steps like solution heat treatment, quenching, and aging. The T6 process involves three main stages: The T7 process is similar but includes an additional or modified aging stage, which improves the alloy’s stability at high temperatures, making it more resistant to stress and deformation. Both quenching and aging are essential for achieving the desired mechanical properties in aluminum alloys. If quenching is not done correctly, it can cause warping or internal stresses. Proper aging ensures that the alloying elements precipitate correctly, leading to stronger and harder materials. Precise temperature control is vital during heat treatment, especially during quenching. Traditional methods often lack the accuracy needed for reliable results. This is where the Thermal Profiling System from Tempsens makes a real difference. Tempsens’ Thermal Profiling System uses a Thermal Barrier Box (TBB-WQ-215), a data logger, and thermocouples to monitor temperature in real-time throughout the T6 or T7 process.      Key Features: Tempsens also provides advanced thermal profiling software that offers deep insights into the heat treatment process. By tracking the quench curve, manufacturers ensure even cooling rates, reducing risks of distortion, cracking, or residual stress. This level of precision helps achieve consistent mechanical properties like hardness and tensile strength. With components like the TBB-WQ-215 thermal barrier box, the Tempsens system ensures accurate temperature control, minimizing defects and improving final product quality. Whether performing T6 or T7 heat treatments, using thermal profiling can boost efficiency, validate processes, and enhance material performance.

FZ Multi-layer Filter Bags are including Oil Absorption Filter Bags,Seamless-absolute Rated Filter Bags,Micronfiber Filter Bags,which are widely application in food and beverage industry ,car and automobile industry,Chemical Industry ,Pharmaceutical industry,Waste water treatment industry ,Metal finishing industry ,it`s welded seams and multi-layers eliminate the possibility of fluid bypass through needle holes ,This unique material composition allows for a higher efficiency, with graded pore-size distribution creating absolute filtration. Thermally bonded microfibers and multi layer create a seamless filter bag that has high tensile strength, providing superior resistance to channeling, unloading, bypass and other forms of traditional leakage that result from pulsating water.

Multi-layer Filter Bags,Oil Absorption Filter Bags,Seamless-absolute Rated Filter Bags,Micronfiber Filter Bags Shanghai Feizuo Environment Technology Co,.Ltd , https://www.fzfilter.com

T6 and T7 Heat Treatment Processes

The Importance of Quenching and Aging

The Role of Thermal Profiling Systems in Heat Treatment

How Thermal Profiling Enhances Quenching and Aging

Benefits of Thermal Profiling

Software for Data Processing and Temperature Analysis

How Thermal Profiling Improves Quenching Accuracy

Aluminium Heat Treatment: An Overview of Thermal profiling system