pulley lagging,rubber sheet,wear resistant,ceramic rubber sheet,Three-in-one impact resistant ceramic composite liner Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

Shaft Grounding Devices: An Economical Solution

Motor shaft voltages can pose a serious threat to surrounding components, particularly motor bearings. When the voltage on a motor shaft exceeds the insulation capabilities of nearby parts or cables, it can lead to both immediate and long-term damage. In extreme cases, this can result in arcing between the shaft and the bearing, causing rapid temperature increases that may permanently damage the bearing through metal vaporization and pitting.

These issues often arise due to various factors such as electrical leakage or induction. External influences, like friction from rubber belts against drive pulleys or other connected machinery, can also contribute to the buildup of shaft voltage. Additionally, AC and DC motors equipped with variable frequency drives (VFDs) are especially prone to generating induced currents on the motor shaft.

The good news is that these harmful effects can be mitigated with the right solutions. Shaft grounding devices are specifically designed to protect bearings by providing a low-impedance path for stray currents to safely discharge to ground. This prevents voltage from accumulating on the rotor and reduces the risk of damaging the bearings over time.

One of the most effective options available is the Helwig Carbon shaft-mounted grounding device. These devices are known for their reliability and cost-effectiveness, offering an efficient way to prevent electrical discharge in a wide range of applications. They are ideal for both AC systems with VFD control and DC motors using PWM drives.

Helwig Carbon grounding devices are available in various sizes, making them suitable for both small and large motors. Their internal mounting capability ensures they can be easily integrated into different setups. They are widely used in industries such as HVAC, pumps, fans, compressors, elevators, data centers, chillers, and conveyors. Additionally, sealed versions are available for use in harsh or contaminated environments, such as wash-down areas.

In terms of economic benefits, installing a shaft grounding device is a smart investment. It helps avoid costly repairs and downtime caused by premature bearing failure. These devices are durable and can last longer than the equipment they are installed on, making them a long-term solution for protecting critical machinery.

They are also easy to install and maintain, with many standard kits available to fit a variety of motor shaft sizes. Whether you're in manufacturing, marine, industrial, or HVAC sectors, grounding devices offer a reliable and efficient way to manage shaft voltage and ensure the longevity of your equipment.

At Emerson Bearing, we recommend the use of shaft grounding devices across a wide range of applications. If you're looking for ways to extend the life of your bearings and improve overall performance, consider downloading our free eBook, *Increase Bearing Service Life and Optimize Performance*, to learn more about how grounding technology can benefit your operations.

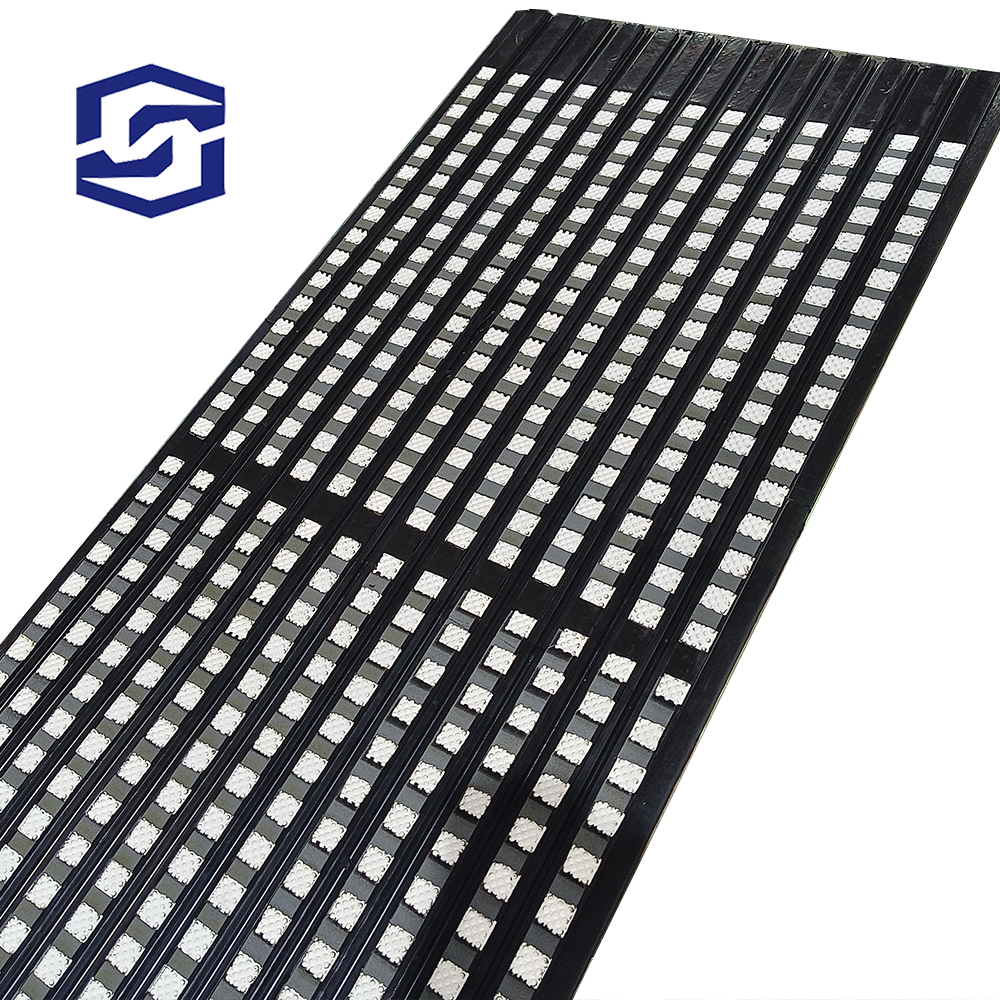

Wear resistant ceramic series, ceramic rubber sheet three-in-one composite liner combines the advantages of ceramic's high hardness and rubber's high cushioning, with wear resistant and impact resistant performance, which can solve the problem of anti-abrasion of the equipment in the process of conveying bulky materials and effectively reduce the environmental noise.

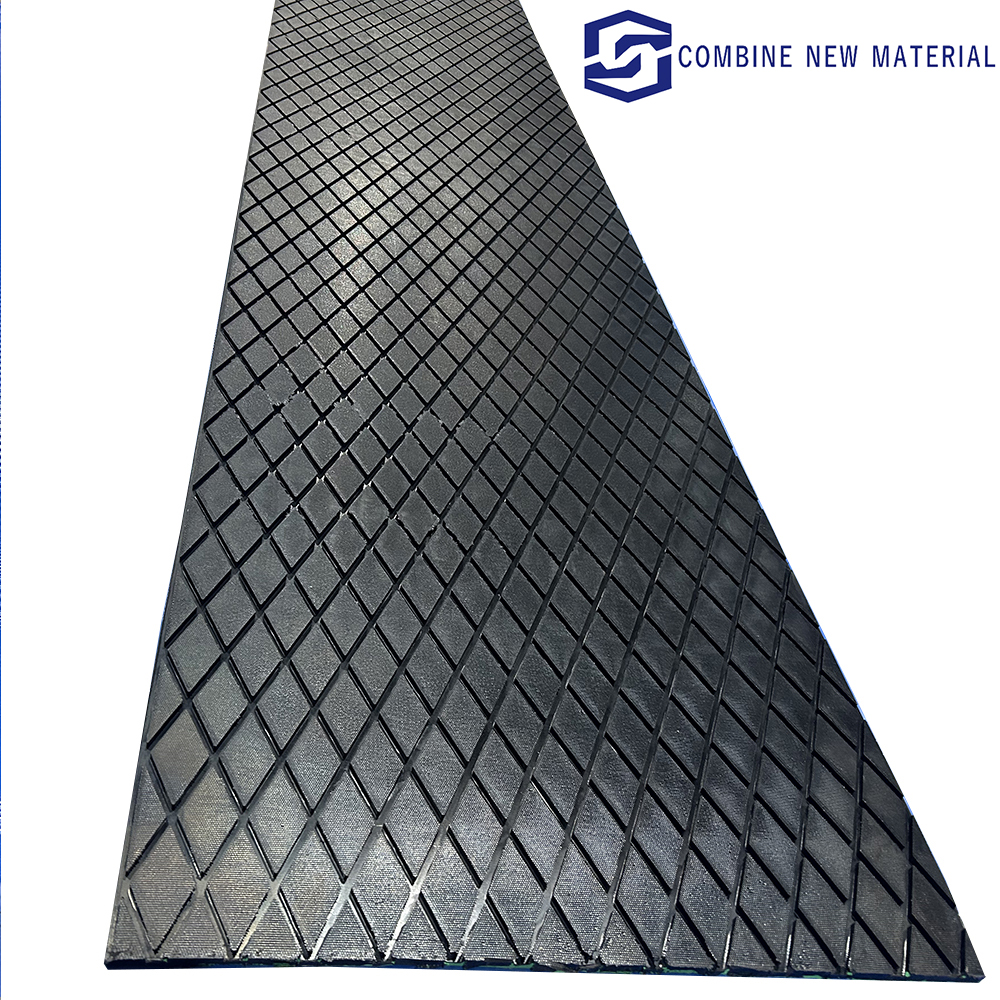

Roller covered is an important part of the belt conveyor transportation system, after covered the roller can effectively improve the operating conditions of the conveyor system, to protect the metal roller from wear and tear, rhombic pattern, ceramic rubber plate coating surface, can increase the friction on the surface of the rubber plate, to prevent the sliding friction between the roller and the belt to reduce the belt slipping, to reduce the roller surface of the material adhesion, so as to reduce the belt deflection and abrasion, so that the roller synchronized with the belt to ensure efficient operation of the belt.