Acoustic emission testing is a non-destructive method used to detect defects in materials by analyzing the ultrasonic stress waves they emit. Unlike other methods like ultrasonic testing, which use an external source of sound waves, acoustic emission testing relies on the natural emissions generated within the material itself when it is under stress. This technique is also known as Acoustic Emission (AE), Acoustic Testing (AT), or Acoustic NDT. In this guide, we will use these terms interchangeably for simplicity and clarity. Acoustic emission testing is one of the most effective and widely used non-destructive testing (NDT) techniques. It allows inspectors to monitor the entire load history of a material without causing any damage. This makes it especially valuable in industries where structural integrity is critical. Historically, AE was considered expensive and only suitable for high-value structures. However, recent technological advancements have significantly reduced the cost of equipment, making it more accessible for a wide range of applications. If you're interested in learning more about non-destructive testing in general, check out our in-depth guide. In acoustic emission testing, sensors are placed on the surface of a material to detect ultrasonic waves that are generated when the material is subjected to stress. These waves travel through the material and change in speed and amplitude when they encounter defects such as cracks or delamination. The frequency range typically used in acoustic emission testing ranges from 20 kHz to 1 MHz. This is well above the range of human hearing, which is why the term "ultrasonic" is often used. Here are some key definitions: Acoustic emissions occur when a material experiences stress, whether from mechanical loads, temperature changes, or internal phase transformations. These emissions are often associated with the initiation or propagation of defects within the material. Common sources of acoustic emissions include: Compared to other NDT methods like magnetic particle or dye penetrant testing, acoustic emission testing is relatively new. It was first introduced in the early 1980s for inspecting polymer matrix composites (PMCs). The technology behind acoustic emission testing relies on piezoelectric sensors, which convert mechanical stress into electrical signals. This concept was discovered in 1880 by Pierre and Paul-Jacques Curie. However, it wasn’t until the 1920s that Walter Cady began experimenting with its use in electronic oscillators. Today, piezoelectric acoustic wave sensors are commonly used to detect and analyze acoustic emissions. While promising, AE is still evolving and requires ongoing research to become a fully reliable inspection method. One exciting emerging application is using AE to detect early signs of earthquakes, though this is still in the experimental stage. Acoustic emission testing is widely used in various industries for detecting defects such as corrosion, leaks, and structural weaknesses. Some common applications include: For composite materials, AE is particularly useful in identifying issues like cracking, delamination, and fiber breakage. Some specific applications include: While both methods use ultrasound, they operate differently. Acoustic emission testing listens for naturally occurring emissions from defects, while ultrasonic testing sends external sound waves through a material to detect anomalies. AE is ideal for monitoring structures during operation and does not require an external energy source. It’s also useful for real-time monitoring in harsh environments. Learn more about ultrasonic testing in our dedicated guide. Acoustic emission testing offers several benefits, including its ability to directly measure failure mechanisms and its non-invasive nature. It can be used in dangerous conditions and provides immediate data. However, it has some limitations. For example, it may not provide detailed information about the nature of a defect and can be difficult to interpret due to weak signals. Pros: Cons: To perform acoustic emission testing, the surface of the object must first be cleaned thoroughly. Then, sensors are mounted on the structure using a couplant like grease or adhesive to ensure good signal transmission. The sensors convert any stress waves into electrical signals, which are then analyzed by inspectors. The number and placement of sensors depend on factors such as the size and complexity of the structure being tested. The Kaiser effect refers to the phenomenon where a material does not produce acoustic emissions until the applied stress exceeds the previous maximum stress it has experienced. This means that certain types of damage may go undetected if the stress hasn't increased beyond a prior level. Acoustic emission testing relies on specialized equipment, including transducers, sensors, and preamplifiers. These devices collect raw acoustic emission data. Common types include piezoelectric transducers, strain gauges, and interdigital transducers. They convert mechanical stress into electrical signals for analysis. Other sensor types include thickness shear mode resonators, displacement gauges, and surface acoustic wave sensors, each designed for specific applications. Low-noise preamplifiers boost the signals from the sensors to make them readable. When combined with proper training, they help identify hidden defects in materials. Acoustic emission testing is often used for informational purposes, but it is also employed in code-compliant inspections. These require adherence to specific procedures and certified personnel. Some of the most widely used standards include: Skid Loader,Mini Skid Loader,Skid Steer Loader,Skid Steer Loader For Sale Shandong Yineng Heavy Industry Co.,Ltd , https://www.yinengloader.comAcoustic Emission Testing: A Comprehensive Guide

How Does Acoustic Emission Testing Work?

What Causes Acoustic Emissions?

The History of Acoustic Emission Testing

Common Applications of Acoustic Emission Testing

Acoustic Emission vs. Ultrasonic Testing

Advantages and Disadvantages of Acoustic Emission Testing

Acoustic Emission Testing Process

The Kaiser Effect

Acoustic Emission Testing Equipment

Transducers and Sensors

A transducer in use on an assembly line

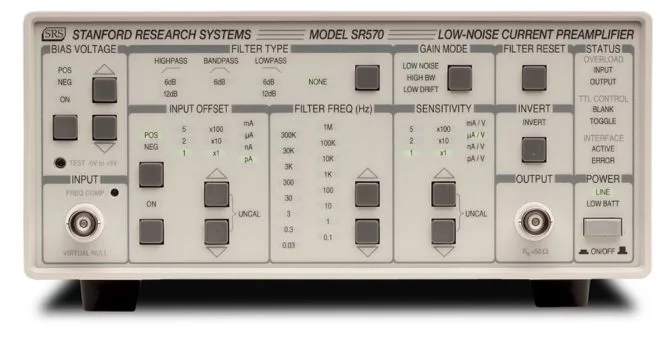

A transducer in use on an assembly lineLow-Noise Preamplifiers

A low-noise preamplifier (source: Stanford Research Systems)

A low-noise preamplifier (source: Stanford Research Systems)Standards and Codes for Acoustic Emission Testing

ASME (American Society of Mechanical Engineers)

ASTM (American Society for Testing and Materials)

CEN (European Committee for Standardization)

Acoustic Emission Testing: A Guide