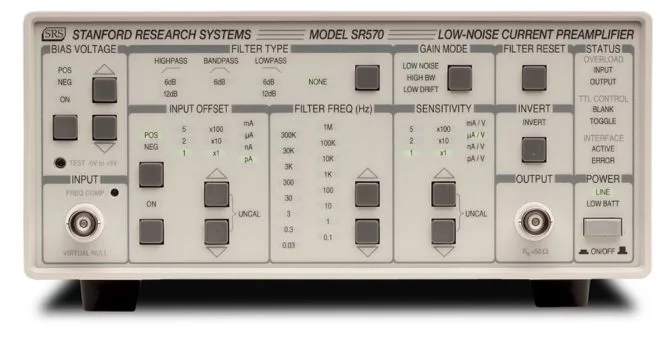

Acoustic emission testing is a powerful non-destructive inspection technique that detects defects in materials by analyzing the ultrasonic stress waves they emit. Unlike other methods such as ultrasonic testing, which introduce external sound waves, acoustic emission testing relies on the internal energy release from the material itself during deformation or failure. This method is also known as Acoustic Emission (AE), Acoustic Testing (AT), or Acoustic NDT. In this guide, we will use these terms interchangeably to make it easier for readers to understand the concept. Acoustic emission testing is one of the most effective and widely used techniques in the field of non-destructive testing (NDT). It allows inspectors to monitor the entire load history of a structure without causing any damage, making it ideal for long-term structural health monitoring. Historically, AE was limited to high-cost applications due to the complexity of the equipment. However, recent advancements have made the technology more affordable and accessible, expanding its use across various industries. Explore our in-depth guide to learn more about the broader field of Non-Destructive Testing (NDT). In an acoustic emission test, sensors are placed on the surface of a material to detect ultrasonic waves generated internally when the material is subjected to stress. These waves can be altered by the presence of cracks, delamination, or other defects, and these changes are analyzed to identify potential issues. The frequency range typically used in acoustic emission testing is between 20 kHz and 1 MHz. This range allows for the detection of subtle changes in wave behavior that may indicate structural problems. Here are some key definitions: Acoustic emissions occur when a material is under stress—whether from mechanical loads, temperature changes, or other environmental factors. These emissions are often associated with structural damage or defects, which are the main focus of AE testing. Common sources of acoustic emissions include: Compared to traditional NDT methods like magnetic particle or dye penetrant testing, acoustic emission testing is relatively new. It gained popularity in the 1980s for inspecting polymer matrix composites (PMCs). The technology relies on piezoelectric sensors, which convert mechanical stress into electrical signals. Piezoelectricity was first discovered in 1880 by Pierre and Paul-Jacques Curie. Its practical application began in the 1920s, and it wasn't until the 1980s that researchers started using it for defect detection in composite materials. Today, AE is still evolving and requires further research to become a fully reliable standalone inspection technique. However, it's already being explored for new applications, such as early earthquake detection. AE is widely used in industries where structural integrity is critical. It helps detect: For fiber-reinforced materials, AE is particularly useful for identifying cracking, delamination, and fiber breakage. Some common applications include: While both methods use ultrasound, they differ significantly. Acoustic emission testing listens for internal emissions caused by defects, while ultrasonic testing sends external waves through the material to detect interruptions. AE is especially useful for real-time monitoring and detecting overloading, and it doesn’t require an external energy source. This makes it unique among NDT techniques. Learn more about ultrasonic testing in our dedicated guide. Acoustic emission testing offers several advantages, including its sensitivity, non-invasive nature, and ability to monitor large structures. However, it also has limitations, such as difficulty in characterizing defects and challenges in signal interpretation. Pros: Cons: To perform acoustic emission testing, inspectors first clean the surface of the object to be tested. They then attach sensors using a coupling agent, such as grease or adhesive, to ensure proper signal transmission. The sensors convert stress waves into electrical signals, which are then analyzed by a monitoring system. Based on the data, inspectors determine the location and severity of any defects. The number of sensors required depends on the size, complexity, and type of material being tested. The Kaiser effect refers to the phenomenon where no acoustic emissions occur until the applied stress exceeds the previous maximum stress the material has experienced. This means that certain types of damage may go undetected if the current stress level hasn’t surpassed the historical threshold. Key components of AE testing include transducers, sensors, and preamplifiers. These devices collect and amplify the signals emitted by the material during stress. These devices are crucial for capturing raw acoustic emission data. Common types include piezoelectric transducers, strain gauges, and interdigital transducers. Interdigital transducers are often used in AE testing because they efficiently convert electrical energy into mechanical waves and vice versa. Low-noise preamplifiers enhance the sensor output, making it easier for inspectors to interpret the data accurately. These devices are essential for distinguishing subtle acoustic signals from background noise. Acoustic emission testing is often used for informational purposes, but it is also applied in code-compliant inspections. Inspectors must follow specific procedures and certifications, depending on the industry and standards involved. Some widely recognized standards include: Shovel Loader,Grapple Loader,Log Grapple Loader,Wheel Loader Grapple Shandong Yineng Heavy Industry Co.,Ltd , https://www.yinengloader.comAcoustic Emission Testing: A Comprehensive Guide

How Does Acoustic Emission Testing Work?

Where Do Acoustic Emissions Originate?

A Brief History of Acoustic Emission Testing

Common Applications of Acoustic Emission Testing

Acoustic Emission vs. Ultrasonic Testing

Pros and Cons of Acoustic Emission Testing

Acoustic Emission Testing Process

The Kaiser Effect

Acoustic Emission Testing Equipment

Transducers / Sensors / Strain Gauges

A transducer in use on an assembly line

A transducer in use on an assembly lineLow-Noise Preamplifiers

A low-noise preamplifier (source: Stanford Research Systems)

A low-noise preamplifier (source: Stanford Research Systems)Standards and Codes for Acoustic Emission Testing

ASME (American Society of Mechanical Engineers)

ASTM (American Society for Testing and Materials)

CEN (European Committee for Standardization)

Acoustic Emission Testing: A Guide