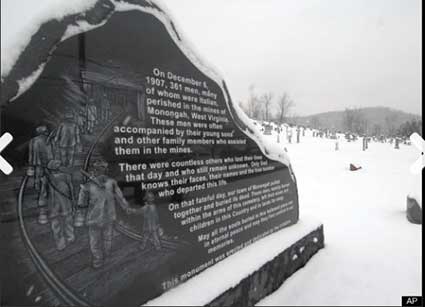

Improving Mining Safety: Building Stronger Futures Mining is one of the most dangerous industries in the world. Every year, accidents like collapses, explosions, and fires claim lives and cause devastating losses. While there has been a major decline in mining-related deaths over the past 100 years—especially since the 1970s—mining remains a high-risk profession. Despite these improvements, tragic incidents still occur, reminding us that safety must always be a top priority. In 1907, the U.S. faced its worst coal mining year, with over 3,200 deaths, including a deadly explosion in Monongah, West Virginia, that killed 361 people. Since then, regulations have improved, but disasters still happen. In recent years, events like the tragic mine explosion in Turkey show that dangers persist globally. Countries like China still struggle with high fatality rates, despite progress in safety measures. The term "mining disaster" refers to any incident that results in five or more deaths. In the U.S., such events have dropped significantly—from 526 between 1901 and 1950 to fewer than 20 since 1976. However, other regions are not as fortunate. For example, in 2010, 33 miners were trapped in Chile for 69 days, and only two weeks ago, five workers died in a collapse in Bosnia. These tragedies highlight the urgent need for better safety solutions. At HJ3, we're dedicated to making mining safer by strengthening the structures that support it. Many mines, especially older ones, suffer from structural weaknesses caused by vibrations, moisture, and chemical exposure. By reinforcing concrete and steel with advanced materials like CarbonSealâ„¢, we help prevent failures and extend the life of these critical facilities. Some of the mines we’ve worked on were so deteriorated that they risked being shut down. With our carbon fiber and glass composite systems, we’ve restored their strength—making them safer and more durable. Our solutions are not only stronger than steel but also lightweight and flexible, ideal for hard-to-reach areas. If you know of a mine in need of structural support, we invite you to partner with us in protecting both workers and resources. Together, we can build a safer future for mining operations worldwide. Contact us today to learn more about how we can help. †â€

Wear Resistant Steel Pipe has overlayer and base material combined through

metallurgy welding. It is properly diluted into base material and can be well

anti impact. We

use an oscillating table with a welding head to arc weld the chromium carbide

into the inside of the pipe. We can handle diameters from 6" to 24"

and then we manufacture pipes from our chrome-plated sheets. The cover layer is

deposited perpendicular to the material flow through the pipe, resulting in a

longer wear life

Typical

materials for cladding in common use at HP Welding include HP700, HP700S,

HP750X, HP750P and stainless steels, as well as many less common alloys.

With

over 30 years of experience on the production of hardfacing products, and the

technical expertise to back them up, HP Welding can meet any base material and

cladding combination.

The

advantages of HP Wear Resistant Steel Pipe

1.

Excellent impact resistance

2.

Easy to process

3.

Good cost performance

4.

Comprehensive quality control

HP Wear Resistant

Steel Pipe can be widely applied to mining site, cement plant, metallurgical

equipment, dredging and power generation and any other fields where need to

combat with abrasion.

Wear Resistant Steel Pipe,Welded Steel Pipe,Drainage Wear Steel Pipe,Construct Wear Stee Pipe HuiFeng Wear Resistant Group , https://www.hpwearsolution.com

Prevent Mining Disasters with Carbon Fiber