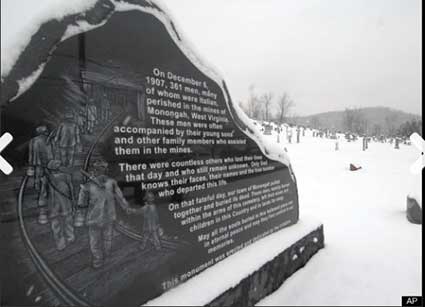

Improving Mine Safety: Building Stronger Futures for Miners Mining is one of the most dangerous industries in the world. Every year, accidents in mines lead to loss of life, often due to cave-ins, explosions, or fires. While there has been a significant decline in mining-related deaths over the past 100 years—especially since the 1970s—mining remains a high-risk profession. Despite progress, the dangers are still very real. In 1907, the U.S. faced its worst year in coal mining history, with around 3,242 miners killed. One of the most tragic events was the Monongah mine explosion in West Virginia, which claimed 361 lives. Although safety regulations have improved dramatically since then, recent disasters, like the deadly explosion in Turkey, remind us that mining risks are far from gone. A "mining disaster" is defined as an incident that results in five or more fatalities. In the U.S., since 1976, fewer than 20 such disasters have occurred, compared to 526 between 1901 and 1950. While the U.S. has made great strides, many countries still struggle with high fatality rates. China, for example, reported over 1,000 mining deaths last year, despite recent improvements. The deadliest mining disaster in history occurred in China in 1942, when 1,549 miners lost their lives. More recently, in 2010, 33 miners were trapped underground in Chile for 69 days before being rescued. Just weeks ago, five miners died in a collapse in Bosnia, and in August, 25 others perished in a rebel-controlled mine in Central Africa. The question is: How can we make mining safer? The answer is clear—by reinforcing mine structures and improving safety systems. At HJ3, we've helped strengthen hundreds of mines in the Southwestern U.S. by reinforcing concrete and steel structures. Many modern collapses are caused by vibrations from heavy machinery, and strengthening support systems can significantly reduce the risk of failure. Some of the mines we’ve worked on were so deteriorated that they were at risk of closure. Using CarbonSeal™’s advanced glass composite and carbon fiber materials, we’ve restored them to better-than-new condition. Our systems are ten times stronger than steel, resistant to harsh chemicals, and ideal for tight or hard-to-reach areas. This technology not only extends the life of mines but also protects workers and resources. If you know of a mine in need of structural support, join us in our mission to improve safety and save lives. Contact us today to learn how we can help protect your mine and its workers. †â€

HP

Wear Resistant Group offers various products of Abrasion Resistant Plate namely

Cr-Carbide Weld Clad Plates, Smooth Surface CCO plate, Heat Treated Wear Plates

(AR Plate or Q&T Steel), Casting Plates, Tungsten Carbide Coated Plates in

various grade and multiple size options.

Abrasion

Resistant Plate is a bi-metal plate consisting of a

low carbon or alloyed steel base plate and a layer of wear resistant deposit.

HP

Abrasion Resistant Plates are made out of unique hard facing process combined

with the specially formulated hard facing alloys produces the harder, tougher

and better wear resistant plates.

The low carbon steel base plate enables the plate to be welded,

bolted or studded to existing structures, while the hard facing provides the

premier wear-resistant surface capable of working in all applicable service

conditions at either ambient or elevated temperatures.

Due to its excellent properties, HP Plates work for long-lasting

service life and superb performance, which are well applied to the industries like Cement Plant, Steel Mill, Mining

Site, Power Generation, Construction where needs combat with abrasion.

Laboratory and field tests have shown that

HP Wear Plates will outwear conventional Wear Plate with single or multiple

hard facing layers by up to six times,

due to conventionally welded overlay plate

having a much lower carbide content, it lacks being homogeneous and has uneven

hardness throughout.

In the following areas, HP Wear Plate has

no equal:

Industrial Applications

Mining, Cement and Brick

Dozer Moldboards. Shovel

Liners. Chute Liners. Dragline Buckets. Classifier Screens. Mine and Quarry

Skips. Pug Mill Paddles. Compactor Rollers. Bucket Lips. Dipper Buckets. Ore

Cars. Ore Scrapers. Dump Truck Body Beds. Loaders and High Lifts. Skid

Plates.

Steel Mills

Blast Furnace. Coke Oven and

Sinter Plants. Skip Car Liners. Sinter Breakers. Ore Bucket Liners. Receiving

Hoppers. Grizzly Bars. Feeder Bins. Conveyor Buckets. Chutes. Spiked Roll

Crushers.

Power Plants

Pulveriser Mills. Cyclones.

Receiving Hoppers. Liner Plates. Coal Handling Systems. Coal Buckets.

Conveyors. Fan Blades and Housings.

General Industry

Grain Chutes. Rub Bars for

Conveyor Chains. Agitator Paddles. Dredge Pump Liners. Grit Blast Liners.

Centrifugal Pump Liners. Mower Skid Plates.

The mechanically strong

interface between the alloy and steel backing is clearly depicted in this

cross sectional photograph of Wear Plate.

Abrasion Resistant Plate,Duplex Wear Resistant Plate,Smooth Hardfacing Wear Plate,Non Cracked Overlay Plate HuiFeng Wear Resistant Group , https://www.hpwearsolution.com

Prevent Mining Disasters with Carbon Fiber