High-efficiency, large-volume culture flasks allow cells to show strong viability with large expression amount of proteins in the culture of mammalian cells and insect cells. During the culturing process, the use rate of the shaker is significantly increased, and the survival rate and viability of cells are both dramatically elevated. NEST culture flasks also provide high repeatability, which allows highly inter-batch consistency of cell growth and yield.

Features:

Erlenmeyer Flasks,Sterile Pc Erlenmeyer Flask,Pc Erlenmeyer Flask,Erlenmeyer Flasks Seal Cap Wuxi NEST Biotechnology Co.,Ltd , https://www.nest-biotech.comTips for Warehouse Fire Safety

With the increasing frequency of fire incidents, maintaining a safe warehouse environment is more important than ever. Fires in warehouses can be caused by a variety of factors, including electrical malfunctions, faulty equipment, and human error. To reduce the risk of such events, warehouse owners and managers must take proactive steps to ensure safety.

A comprehensive fire prevention strategy involves regular maintenance, staff training, and the use of effective fire detection systems. By implementing these measures, businesses can significantly lower the chances of a fire occurring and protect both people and property.

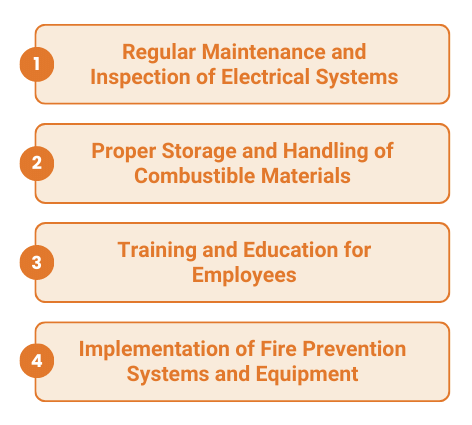

Four Essential Tips for Preventing Warehouse Fires

Fire prevention requires a multi-layered approach that includes proper maintenance, employee education, and the installation of fire protection systems.

Here are four key tips to help keep your warehouse safe:

1. Regular Maintenance of Electrical Systems

Electrical issues are one of the leading causes of warehouse fires. To prevent this, schedule routine inspections of all wiring, panels, and electrical devices. This helps identify potential hazards before they become serious threats.

2. Safe Storage of Flammable Materials

Items like cardboard, wood, and paper are highly flammable and should be stored away from heat sources and electrical equipment. Ensure materials are stacked properly to avoid tipping or collapse, which can create fire risks.

3. Employee Fire Safety Training

All employees should be trained on how to handle flammable materials and recognize fire hazards. They should also know how to use fire extinguishers and follow emergency procedures in case of a fire.

4. Installation of Fire Detection and Suppression Systems

Smoke detectors, alarms, and sprinkler systems are essential tools for early fire detection and control. These systems provide critical time to respond and minimize damage.

Preparing for Emergencies: The Importance of an Emergency Response Plan

An emergency response plan is vital for ensuring the safety of everyone in the warehouse during a crisis. It outlines clear procedures for evacuation, communication, and accountability.

Your plan should include designated roles, marked exit routes, and a reliable communication system. Regular drills and updates are necessary to ensure effectiveness.

By having a well-prepared plan, you can protect lives and reduce the impact of any incident.

Protect Your Warehouse with MoviTHERM’s Advanced Fire Detection Solutions

Preventing warehouse fires is crucial for protecting your team, assets, and business operations. MoviTHERM offers innovative solutions designed to detect early signs of fire and monitor equipment conditions.

Their thermal imaging cameras can identify temperature changes that may indicate a developing fire, even in areas where traditional smoke detectors might not work effectively. This early warning allows for quick action to prevent major damage.

In addition, MoviTHERM’s condition monitoring systems help detect equipment failures before they lead to overheating or fire. Real-time alerts enable managers to address issues proactively, reducing the risk of a fire starting in the first place.

With MoviTHERM’s advanced technology, warehouse managers can take a proactive approach to fire safety, ensuring the protection of their people, property, and business continuity.

Warehouse Fire Safety Tips

1.PC bottle, which meets the USP Class 6 Standard, with high transparency, has strong impact resistance, oxidation resistance and can withstand a high temperature up to 121℃.

2.There`s a scale made by injection molding on the flask body to facilitate observing the filled liquid volume.

3.Sterilized by E-beam, SAL=10^-6.

4.Non-Pyrogenic, DNase/Rnase free.

5.Individually packaged in sterile bag.